EXPERTISE

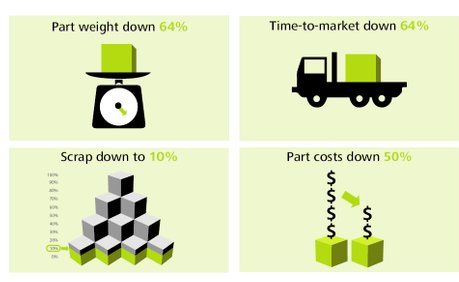

inovo_ aims to create a shift in the production process and technology selection. Based on our knowledge and expertise we recommend the optimal material for the job and lead the redesign. By doing so we enable a potential weight reduction up to 64% with parity strength. On top, optimized low volume production techniques can save up to 50% on part cost with just 10% scrap versus normal production. The lean production process will allow producing on direct market demand. (Data from Deloite University Press)

EXAMPLES

Via additive manufacturing, like direct metal printing, it is possible to significantly reduce part weight without trade-offs in strength or rigidity. This production technique allows to form inner support structures which can't be made with conventional methods.

Latest topology CAD software allows us to define the optimized shape and design for functionality instead of manufacturability. This reduces excessive scrap material and increases overall efficiency.

The focus is low setup cost and production on demand. We will always screen for the best material and production process focussing on low volumes. The production process needs to fit the size of the prize and allow for all agility the modern markets demands.

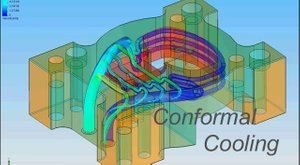

The combination of flow simulation software and additive manufacturing techniques allows us to optimize cooling channels. Improved mold cooling can reduce cycle time up to 30% resulting in significant output gains.

Additive manufacturing allows a monolithical design. This enables a slimmed down assembly process and the production of complex shapes with a higher reliability.